Statutory Section

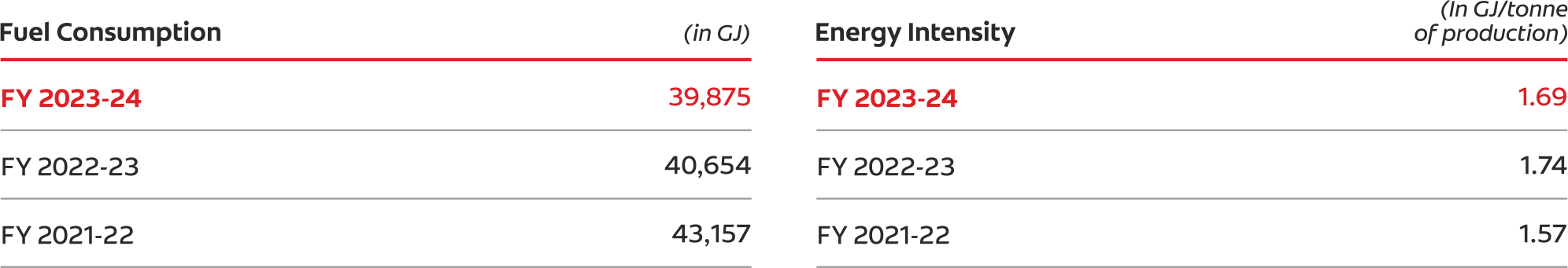

We're implementing measures in vital environmental areas to meet our SMILE-based targets. In energy and emissions, we're improving fuel efficiency, reducing power consumption, and transitioning to cleaner energy sources.

Regarding waste, we prioritize reduction, reuse, and recycling efforts to minimize landfill waste. Additionally, we employ rainwater harvesting to conserve water resources and reduce the strain on freshwater sources.

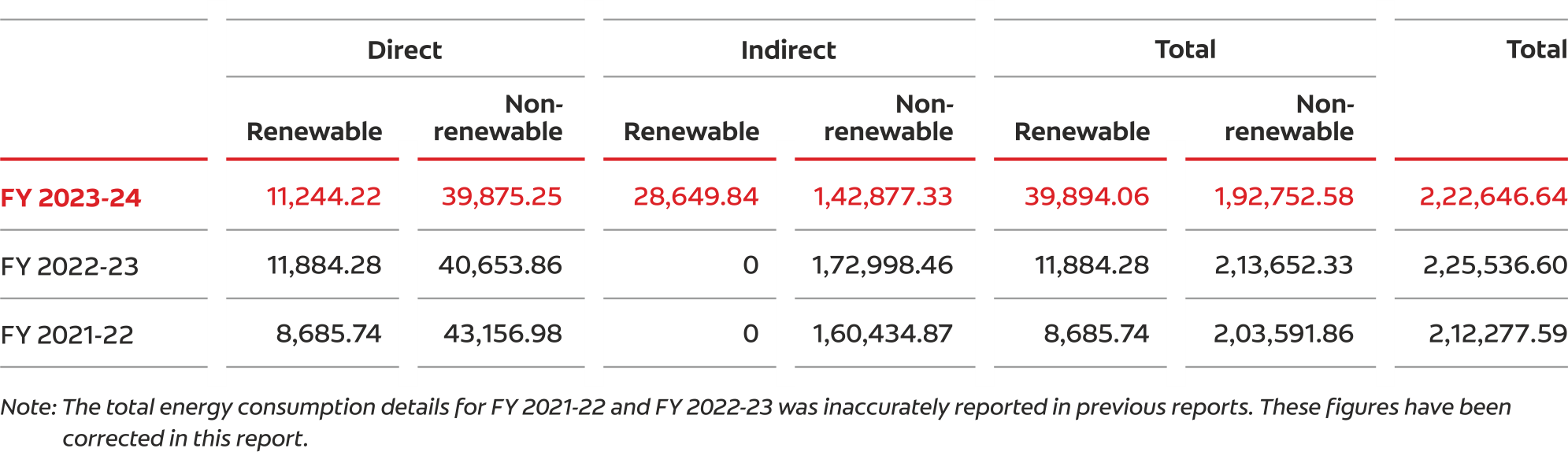

In FY 2023-24, we utilized approximately 222.64 TJ of energy, across all our Indian sites, with 18% sourced from renewable energy sources like solar and wind.

The energy mix too has shown a positive trend with the share of renewable energy in total consumption increasing by 236% and that of non-renewable energy reducing by 14% over the previous year.

Note: We included our Head Office, Mumbai in last year's report to provide a more comprehensive overview of our sustainability performance. As a result of this change, year-on-year data is not directly comparable with FY 2021-22 data.

To help support our ambitious targets around climate action and Net Zero carbon transition, and to address our climate-related risks and opportunities, Colgate-Palmolive Company, our parent organization, focuses our climate strategy on five interconnected pillars:

Supply chain engagement | Net zero carbon operations | Sustainable products & consumers | Business reliance | Society & Nature

Underlying Colgate-Palmolive Company's climate commitments are science-based targets focused on a transition to Net Zero Carbon emissions. Since 2015, our parent organization has engaged with the Science-based Targets Initiative (SBTi) to set meaningful climate targets aligned with the most ambitious designation available through the SBTi process.

In September 2022, SBTi approved Colgate-Palmolive Company, USA's updated near- and long-term science-based emissions reduction targets and Net-Zero science-based target, indicating our continued climate leadership.

We replaced existing conventional blowers of Air Handling Units with Electronically Commutated (EC) Fans at Baddi, reducing both emissions and cost. Collaborating with the supplier, we conducted thorough benchmarking for energy-saving potential. The retrofitment achieved an annual energy saving of 60,000 kWh.

To know more about the AI-based integrated metering and monitoring systems implemented across our operation, please see the Outperform section of this chapter.

Since 2013, Colgate-Palmolive Company has used the Leadership in Energy and Environmental Design Green Building Rating System of the U.S. Green Building Council as one way to reduce overall exposure to water and climate change-related issues and offer a healthier, more comfortable work environment. Two facilities in India, Sri City in Andhra Pradesh and Sanand in Gujarat, are LEED Gold Certified.

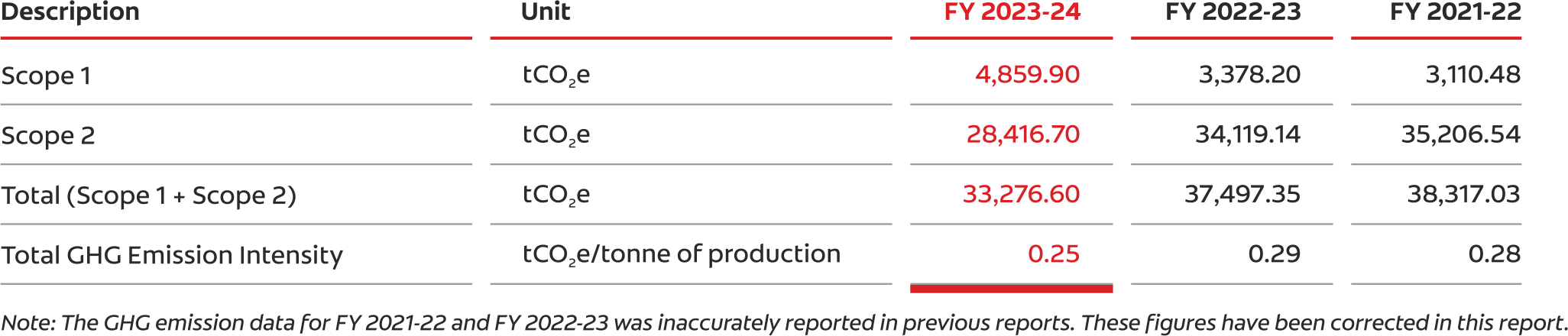

In FY 2023-24, we observed a 11.3% decrease in our carbon emissions, reporting 33,276.6 tCO e 2 which can be attributed primarily to a higher portion of renewable electricity usage in plant operation and replacement of diesel with PNG. The table below illustrates the changes in our Scope 1 and 2 emissions, as well as our GHG intensity, over the last three years.

* vs a regular fluoride toothpaste

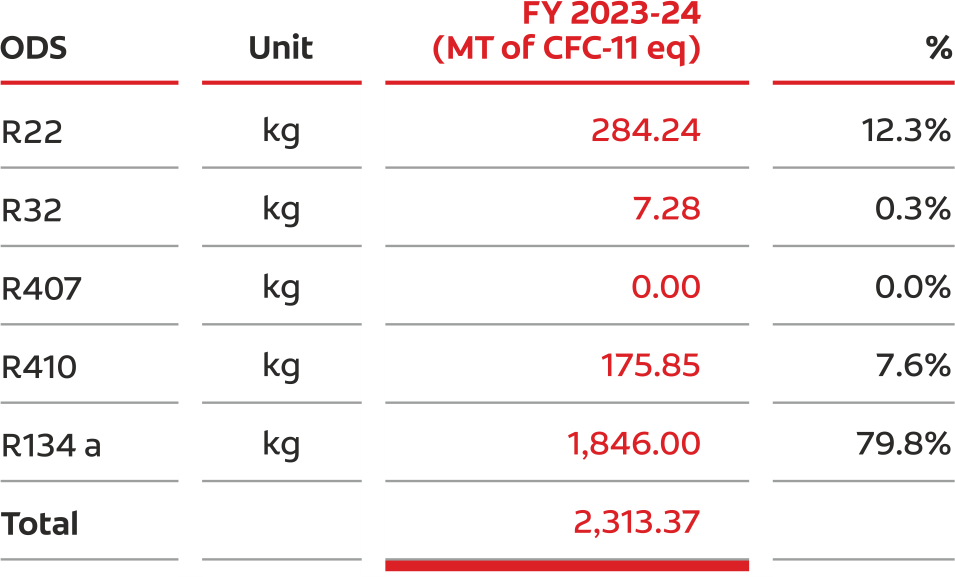

In FY 2023-24, our consumption of CFC-11 eq. Ozone Depleting Substances (ODS) was 2.313 MT. We are planning to adopt the latest pollution control equipment to ensure higher energy efficiency and reduce fugitive emissions.

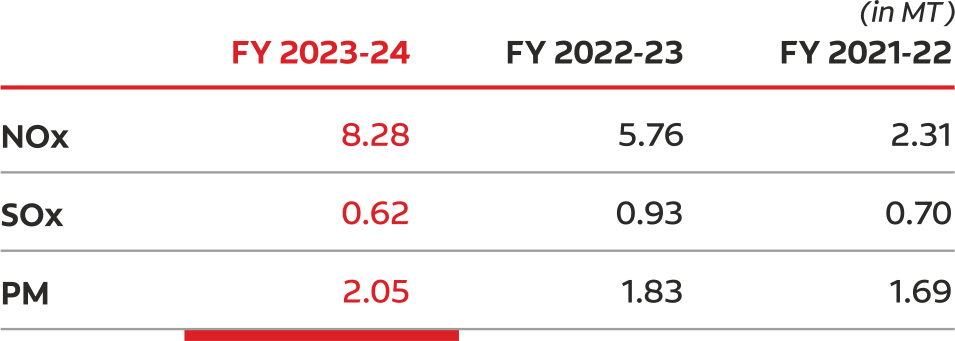

Increase in emission level is driven by higher usage of DG due to disruption in electricity grid supply and higher running hours for boilers due to increase in volume and new products

Baddi, Himachal Pradesh

High-Speed Diesel (HSD) is a significant contributor to carbon emissions. To switch over to an alternate, cleaner fuel, we chose Natural Gas (NG) as a fuel for the boiler and worked closely with the supplier to expedite the pipeline process for supply. After successful coordination with the requisite vendors, the natural gas project was implemented in January 2024.

The change yielded significant environmental benefits. The site achieved a 15% reduction in CO 2 emissions associated with boiler operations in the pilot phase. It not only contributed to mitigating the site's carbon footprint but also aligned with broader sustainability objectives and efforts to combat climate change.

Plans are underway to benchmark the system at Baddi so as to implement them across other feasible locations.

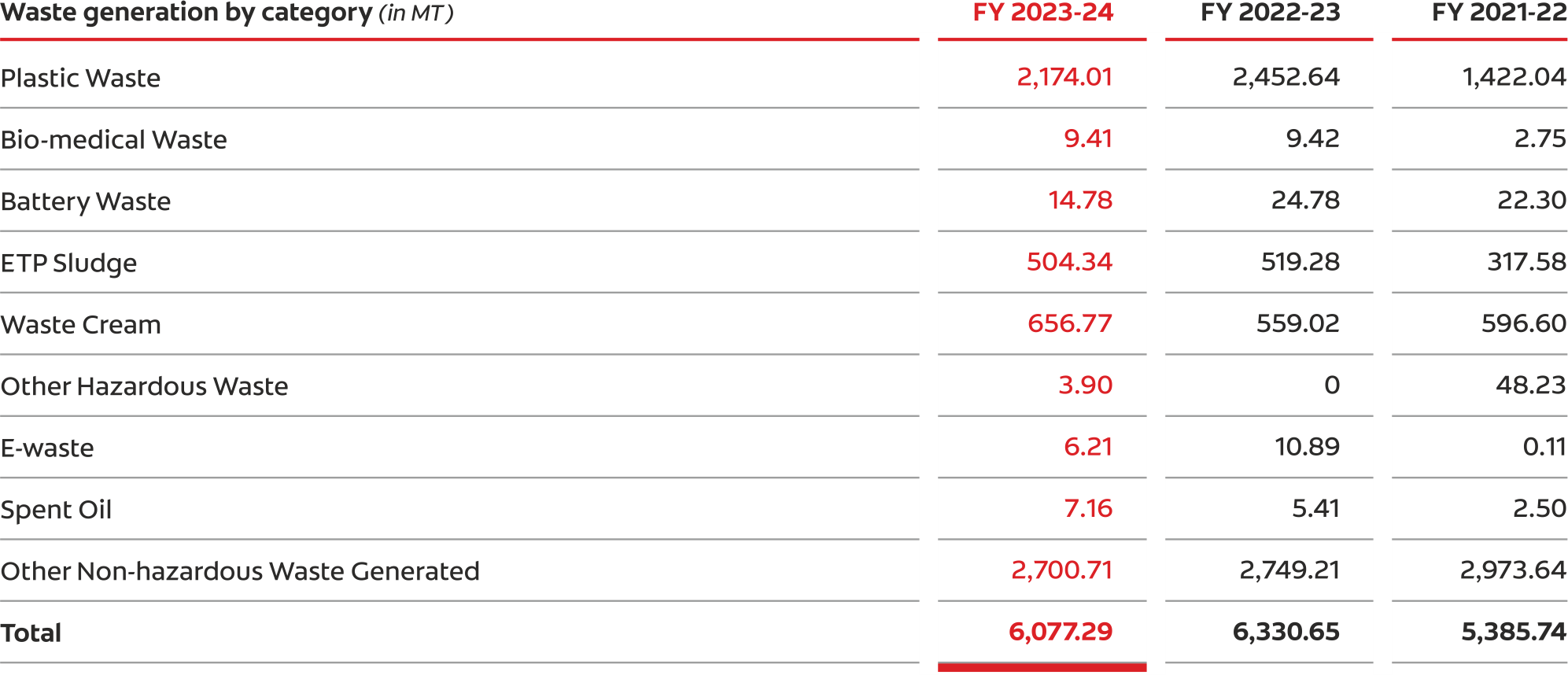

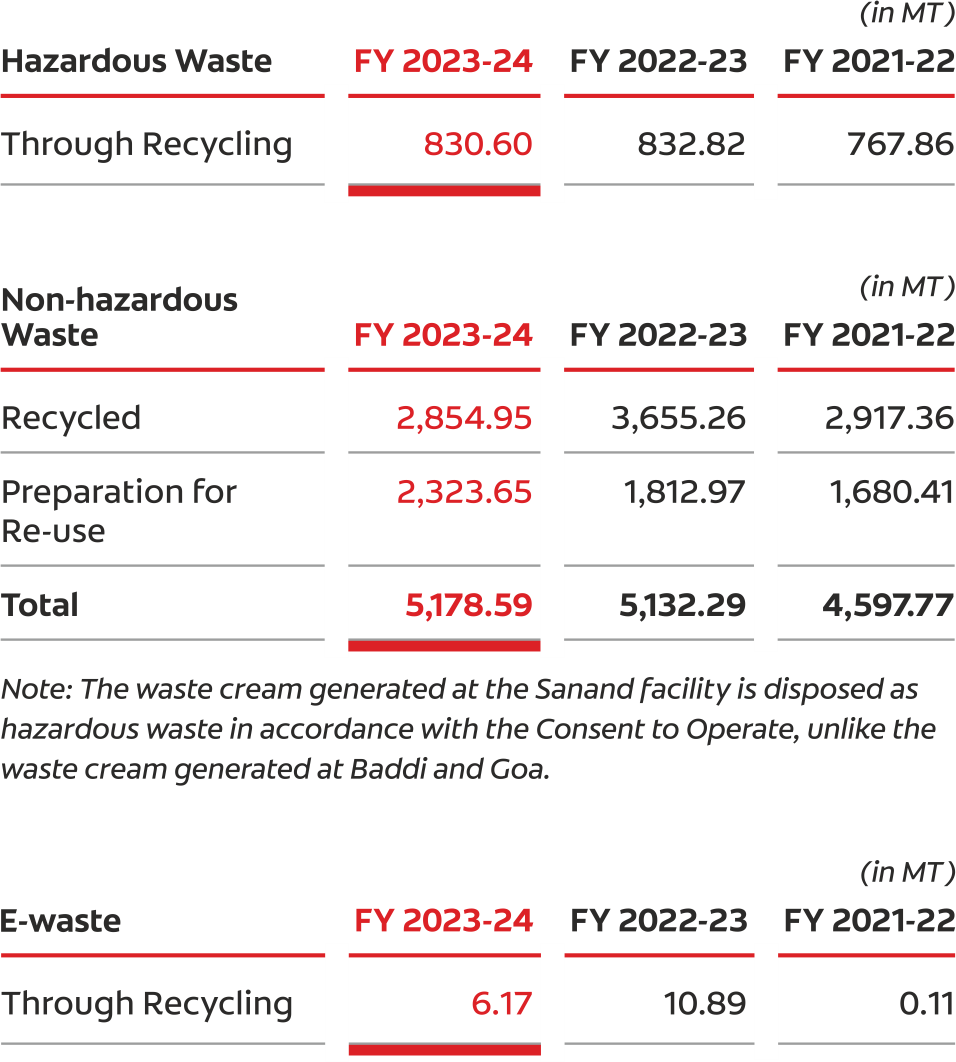

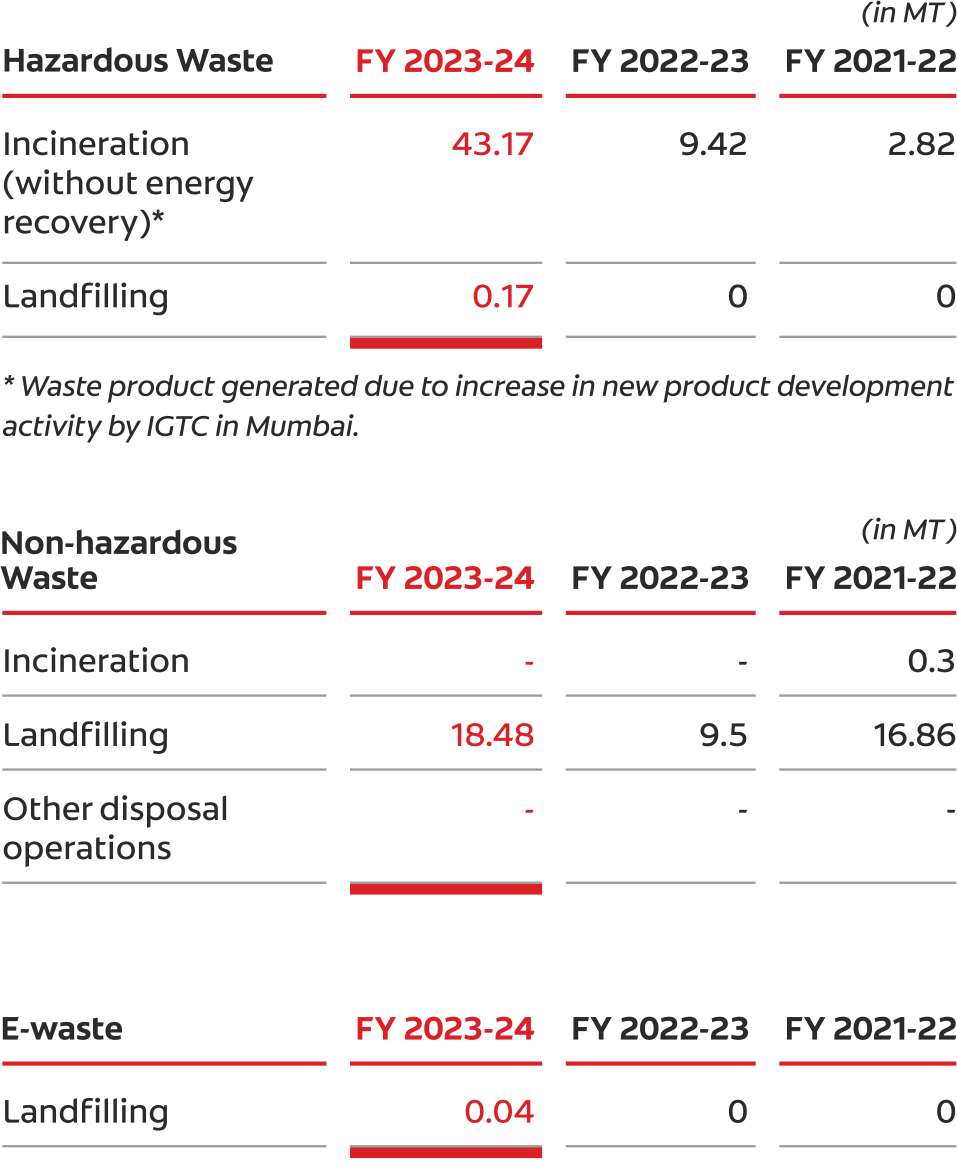

Our waste management strategy follows circular principles, minimizing environmental impact and maximizing social benefit.

In our manufacturing processes, waste can originate from various sources. To address this, we classify and segregate waste, employing advanced monitoring systems to identify and capitalize on reduction opportunities. By analyzing waste trends and implementing targeted interventions, we continuously optimize resource utilization. Our initiatives are designed to promote responsible waste management, reflecting our unwavering commitment to a sustainable future.

Note: The figures of total waste generated in FY 2021-22 and FY 2022-23 have been corrected, as compared to previous report.

Waste management projects initiated in FY 2022-23 were streamlined and scaled up this year, resulting in a positive trend.

Note: The figures of total waste generated in FY 2021-22 and FY 2022-23 have been corrected, as compared to previous report.

Waste management projects initiated in FY 2022-23 were streamlined and scaled up this year, resulting in a positive trend.

We successfully diverted 6,015.36 MT of waste in FY 2023-24, of this 3,695.67 MT was recycled and 2,319.69 MT was reused.

Sanand, Gujarat

To reduce paper consumption and streamline shop floor processes related to quality, safety, and machine checks, our team in Sanand implemented a paperless office solution through digitization. Collaborating closely with the global engineering team and a renowned OEM partner, our plant digitization team ensured compliance with CFR 21 11 regulations and established guidelines and standards for the rollout.

Following a successful implementation across 100% of operations in Sanand, we are now planning to extend the paperless initiative to ancillary functions and support channels, further enhancing efficiency and sustainability throughout our operations.

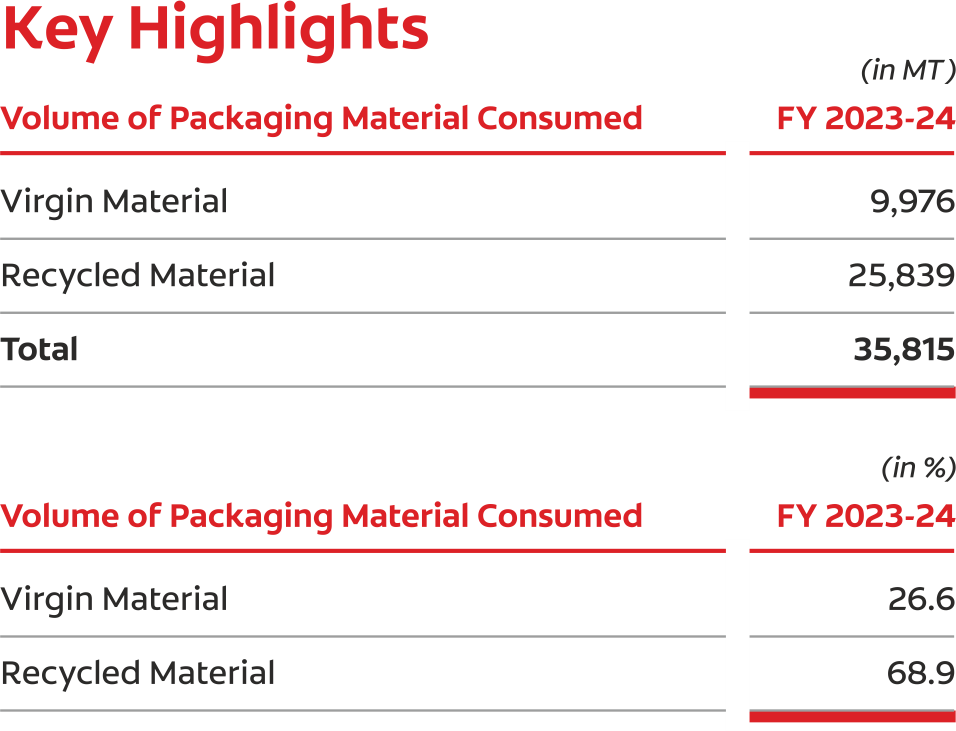

We invest in sustainable packaging, aiming to minimize waste and maximize recyclability. By the end of 2025, our target is to eliminate one-third of virgin plastics and ensure all plastic packaging is recyclable, reusable, or compostable. Analyzing trends, we implement measures to reduce our waste footprint, contributing to responsible waste management. Additionally, we prioritize research and development for innovative materials and packaging designs, aiming to reduce reliance on virgin resources and foster a circular value chain.

Colgate-Palmolive Company, USA launched the first of its kind Recyclable toothpaste tube which is made of HDPE*. We chose this material because the HDPE bottle stream has one of the highest recycling rates across the world. But It was not easy to work with; HDPE is rigid and not well suited for squeezable tubes. But by combining different layers of HDPE laminate at varying thicknesses, our engineers were able to produce a soft, easy-to squeeze recyclable tube with similar performance parameters.

We shared our recyclable tubes knowhow globally, including with our competitors. We, thus, promoted the transition to recyclable tubes, improving portfolio efficiency and contributing to a circular economy. We are committed to transition 100% of our toothpaste portfolio to recyclable tubes by 2025 in India.

During FY 2023-24, 83% of the total packaging by weight was recyclable. High-Density Polyethylene (HDPE)

Under EPR, in FY 2023-24, we collected 37,466 MT of plastic (including packaging), of which 25,839 MT was recycled, and 11,627 MT was safely disposed.

Additionally, all the pre-consumer plastic waste generated at the manufacturing site is sent for responsible recycling through an authorized waste handler, who ensures responsible collection, sorting, and recycling/ co-processing of the uncontaminated

Providing access to safe water, improved sanitation and proper hygiene education is an important aspect of our water stewardship strategy at Colgate. We're committed to achieving Net Zero by embracing a comprehensive water management strategy. This involves prioritizing resource efficiency, monitoring consumption patterns, and minimizing waste to reduce our environmental impact.

We promote innovative solutions to decrease water usage and utilize advanced data monitoring systems for effective tracking. Tools like the World Resource Institute's Aqueduct help us anticipate future needs and identify areas of water stress.

We prioritize freshwater conservation and efficient water treatment practices to ensure availability for surrounding communities. Despite challenges in water-stressed regions like Sanand and Baddi, we're committed to comprehensive conservation efforts to achieve net zero water. On the other hand, our Sri City plant in Andhra Pradesh and Goa facility have implemented water-harvesting initiatives, achieving water positivity.

CPIL utilizes various water sources, including groundwater, municipal water supply, industrial corporation sources, and rainwater. In FY 2023-24, we replenished over 191,412 KL of rainwater from all our operational locations.

We employ advanced technologies to monitor wastewater quality continuously, thereby minimizing its impact on water bodies. Our facilities feature 3-stage water treatment plants, including tanks, clarifiers, mixers, and filters. Parameters like pH, BOD, COD, color, fluorides, and TSS are rigorously measured to ensure compliance with pollution control standards. Treated water is reused for cooling towers, boilers, and gardening, aligning with our commitment to sustainable water management.

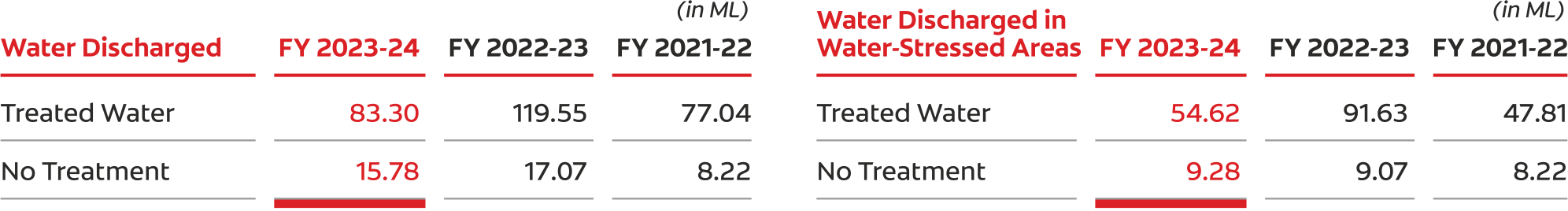

In FY 2023-24, we discharged a total of 99 ML of water, of which 65% was utilized for gardening within our premises.